P-2000 Laser-Based Micropipette Puller

The P-2000 micropipette puller represents a significant advance in the technology of fabrication of micropipettes, optical fiber probes, and nanospray tips. The P-2000 integrates a CO2 laser-based heat source with the technology derived from our extensive experience with conventional pullers. This system offers capabilities unmatched by other pullers.

COMMON APPLICATIONS P-2000

P-2000/G

- Patch clamp – single isolated and whole cell

- Intracellular recording

- Microinjection

- Nano probe research

- SECM

P-2000/F

- Nanospray mass spectrometry

- NSOM

- Tapering optical fibers

FEATURES

- Capable of pulling quartz, borosilicate and aluminosilicate glass.

- Fully programmable – including heating filament characteristics.

- The laser has no melting point limit as with conventional metal filaments; and therefore, cannot be burned out.

- Pulls electrodes with tip diameters smaller than 0.03µm.

- Optimized velocity sensing circuit for maximized sensitivity and reproducibility.*

- Operating life of the CO2 laser is expected to be in excess of ten years with normal use, after which the laser can be refurbished by the Sutter Instrument Company for a nominal charge.

- Individual programs can be write-protected in order to secure them from inadvertent changes.

- The total time that the heat is on during the pull is displayed for improved program development and troubleshooting.

- A date and time stamp is displayed to show the last time that a program has been changed.

- The P-2000/F is ideal for applications such as nanospray and NSOM.

- Preprogrammed sample programs for intra-cellular and patch pipettes. The P-2000/F also comes with an NSOM tip program.

P-1000 Next Generation Micropipette Puller

Developed through years of experience with the Flaming/Brown style micropipette pullers and infused with leading edge technology, Sutter is proud to introduce the P-1000 micropipette puller. The most obvious new feature is the color touchscreen display that provides an intuitive and full-featured interface.

COMMON APPLICATIONS P-1000

- Patch pipettes

- Sharp electrodes

- Pronuclear injection

- Zebrafish injection

- Insect egg injection

- Aspiration pipettes

FEATURES

- Color touch-screen display

- Safe heat mode to protect and extend filament life

- Pipette Cookbook program directory

- Pre-heat mode improves stability

- Line repeat mode simplifies multi-line programming

- Help topics and error detection

- Glossary with micropipette and puller terminology

- Copy & Paste function for writing new programs

- Jaw temperature sensor helps define ideal pulling conditions

- Record of last two pull results

- Ramp test more easily accessed and can now be stored and referenced within each program. Helps to establish program heat settings and protect filament.

- Two symmetrical pipettes with each pull

- Self-contained air supply with filtration system and humidity control chamber

- Memory storage for up to 100 programs

- Two cooling modes: time and delay

P-97 Flaming/Brown Micropipette Puller

The P-97 Flaming/Brown type micropipette puller is ideal for fabricating micropipettes, patch pipettes and microinjection needles. While retaining many of the features of earlier models, the P-97 offers improvements in mechanical, electronic and software design. The result is better control of the pulling process and a higher degree of reproducibility. The P-97 combines a proven mechanical system with a sophisticated, programmable microprocessor controller. This programmable control of the pulling parameters allows the investigator to design application specific pipettes from a wide range of glass compositions and sizes

COMMON APPLICATIONS P-97

- Patch pipettes

- Sharp electrodes

- Pronuclear injection

- Zebrafish injection

- Insect egg injection

- Aspiration pipettes

FEATURES

- Environmental chamber for humidity control

- Programmable air pressure

- Memory storage for up to 100 programs

- Write protection and date stamp for each program

- Two symmetrical pipettes with each pull

- Two cooling modes: time and delay

- Preprogrammed sample programs for intracellular and patch pipettes. Special programming on request

- Ramp test – self test for establishing program heat settings when a new filament or glass is introduced

- Vacuum fluorescent display

- Constant current power supply for filament and pull solenoid

- Looping pull cycle for fabrication of patch type micropipettes

- Self-contained air supply with filtration system and humidity control

- Consistent and reliable electrodes with tip diameters less than 0.1µm

- Control over the time and pressure at which the air is delivered

- Optimized velocity sensing circuit for maximized sensitivity and reproducibility

- Quality control, SEM photograph of a tip pulled with each puller; criterion is tip measurement less than 0.1µm and typically is ~0.06µm

P-30 Vertical Micropipette Puller

The model P-30 vertical micropipette puller is designed for the fabrication of basic micropipettes and patch-type pipettes. It will pull micropipettes with tip diameters as small as 0.3µm and moderate taper lengths (6 to 10mm). By using an included patching attachment, the P-30 will pull the standard double pull patch-type pipette. Used with thin wall glass capillaries, it will generate pipettes or needles suitable for microinjection studies. The P-30 is ideal for student laboratories and other situations which call for an economical, reliable pipette pulling device.

COMMON APPLICATIONS P-30

- C. elegans

- Xenopus

- Drosophilia microinjection

FEATURES

- Pulls electrodes with tip diameters down to 0.3µm, consistently and reliably.

- A micrometer allows precise reproducibility of trip point settings in producing fine microelectrodes.

- Full three digit digital controls for accurate setting of heat and pull values.

- Constant current power supplies for filament and pull solenoid.

- Enclosed front to reduce variability caused by drafts.

- Dual (manually) switched heat settings for patch pulling or two different types of micropipettes.

- All working parts are made from corrosion resistant material.

- Two heating assemblies available; platinum/iridium (recommended) or Nichrome coil.

- Built-in RFI filter and dual voltage/dual frequency operation.

- Rubber padded jaws to minimize breakage of capillary tubing.

- Designed to take up a minimum of bench space.

- Slope of the front panel aids in preventing glass from entering cabinet/solenoid mechanism.

Capillary Glass & Filaments

Sutter Instrument Company, in addition to the finest micropipette pullers available, offers a wide selection of high quality capillary glasses in various sizes and materials. Though there are many types and sizes of capillary glass available, we have carefully selected only those that pass our criteria. Our expertise in micropipette technology assures you of precision and high quality.

We offer capillary glass tubing in three different compositions; quartz, borosilicate and aluminosilicate. Each composition has its own unique properties and the selection will be determined by your application and your puller’s capabilities.

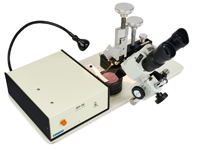

BV-10 Microelectrode Beveler

Elegant and simple to use, the BV-10 offers precision beveling of micropipette tips between 0.1 and 100µm. The unique abrasive plate drive system is vibration free for greater control of the beveling process. Beveling can be accomplished very rapidly and produces consistent tip diameters using the techniques as described by Brown and Flaming, Science, August 1974, Vol. 185.

Intracellular recording electrodes can benefit from beveling because of:

- A reduction in the tip diameter by creation of the sharp point on the electrode

- A lowered electrical resistance of the electrode due to the larger cross sectional area of the lumen.

COMMON APPLICATIONS BV-10

- Deep brain injections

- ES cell and ICSI procedures

- C elegans injections

- Fish and insect egg injections

FEATURES

- Vibration-free, magnetically coupled beveling surface

- Abrasive surface optically flat to a half wave (250nm)

- Finest abrasive surface commercially available

- Synchronous clock motor insures stable rotation rate

- 7lb steel baseplate adds additional dampening

- Integrated LED lamp

- Robust micromanipulator controls bevel angle and advancement